20 May 2022

Fastdry: a breath from perfection

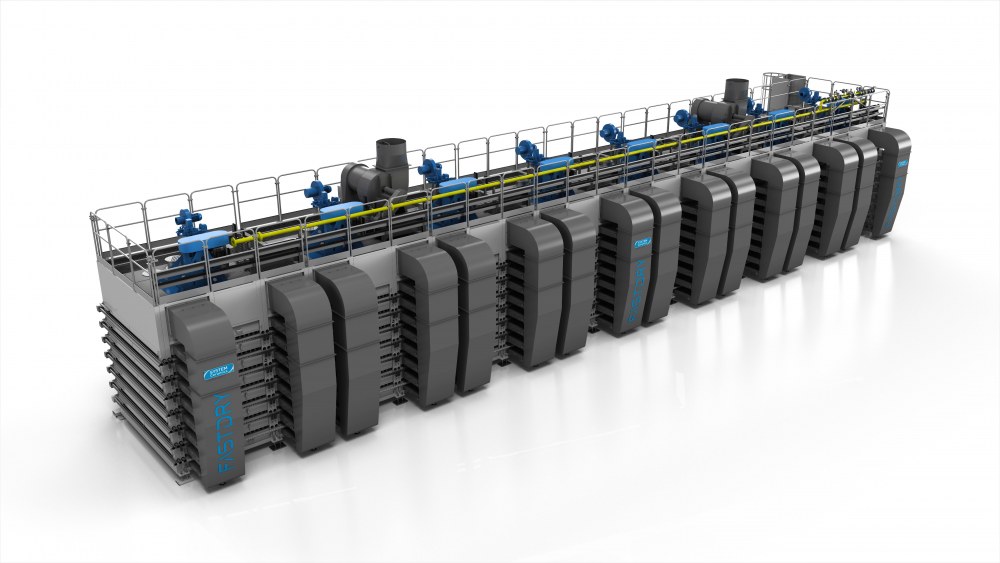

The ceramic world is in continuous transformation, and with it also our know-how and our offer, which increasingly aim at optimizing the complete ceramic production cycle, with an all-encompassing, high-performance vision. After the launch of devices of technological excellence in the pressing, decoration and quality control areas, System Ceramics’ latest project makes its debut in the thermal machine sector, with an innovative and unique approach: this is Fastdry, the first horizontal multi-channel drying machine with independent chambers fitted with air suction and blowing boxes.

Airflow under control

Fastdry is a dryer meticulously designed in every technical detail for achieving unmatchableperformance levels from a production and quality point of view. Equipped with independent chambers fitted with air intake and blowing boxes, this machine guarantees an optimal control of airflows with the result of obtaining uniform drying throughout the tile or slab surface. The distribution of air through a system of chambers serves not only to separate the different levels, but is also a means for transporting volumes of air, for both the input and output phases. And to finish, every chamber is equipped with a number of independent channels, inside of which it’s possible to introduce air, controlling its circulation, guaranteeing uniform drying.

Controlled versatility

Its particular structure makes Fastdry a particularly innovative system: the possibility of regulating the airflows and guaranteeing control and stability at all times allows for an optimal management of consumption by the machine, avoiding energy wastage or drops in production. Maximum versatility is achieved with Fastdry thanks to the separation of levels, which coincides with the ability to simultaneously process products with different drying times. In its passage through Fastdry, a tile or slab undergoes a uniform and complete drying, preparing the ceramic product for the subsequent decoration and firing phases and avoiding the onset of problems during subsequent processing phases: the integrity of physical and structural properties is unmatched.

Optimized interconnection

Like all System Ceramics’ latest-generation technologies, the entire Fastdry process is integrable with Prime, the software services platform designed and developed internally, which has a simple and user-friendly operator interface allowing for simplified and total management of the machine and production. A further element of technological innovation relates to the software developed by System Ceramics’ engineering team which permits the management and tracking of the multi-product inside the machine.

Advantages of high speed

Fastdry can be fitted with a high-speed rapid output module to evacuate slabs or tiles with a thickness of 3 to 30 mm, ensuring uniform temperature values and therefore guaranteeing a reduction in problems in the decoration phase, differences in tone, any organic difference between the different tiles, besides an increase in yield in the application of effects. Fastdry is innovative from every point of view: consumption under control, drying precision and uniformity, low levels of necessary maintenance, simplicity of use, management optimization: a customer-oriented design, and the ability to meet every need for achieving excellent quality results.

Visit Fastdry web page, download the brochure and find out more.