The digital printer with a computing power never seen before.

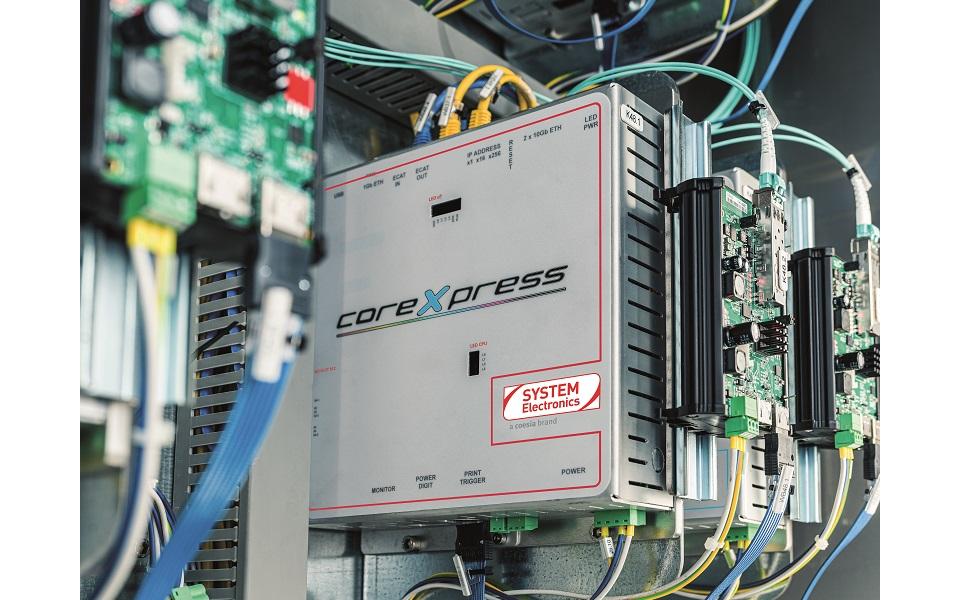

Creadigit Infinity is the evolution of digital decoration. Information useful for reproducing images onto the ceramic surface is processed and managed in real time thanks to the cutting-edge architecture combined with the control modules of the CoreXpress platform. With latest-generation electronics developed by the Electronics division, Creadigit Infinity boasts extraordinary computing power. More flexibility, more configuration variability with more than 12 bars and the possibility of working with different head models, is just the beginning.