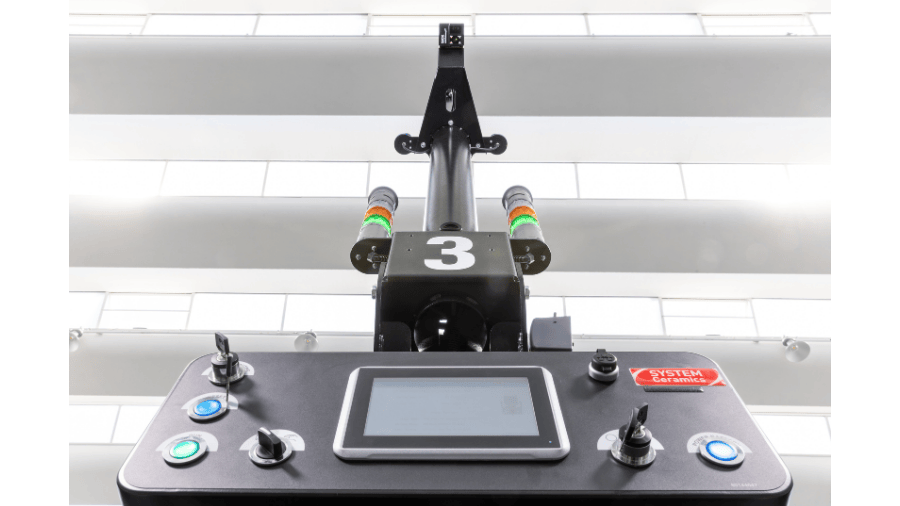

I-GV: totally efficient handling

At a time of growing need for better operational efficiency in warehouses and production facilities, System Ceramics responds with its renowned know-how presenting its I-GV range of automated guided vehicles for even more efficient logistics processes. These state-of-the-art vehicles simplify end-of-line management, handling different types of load units and assuring optimized interaction with all storage systems.

A versatile and robust range of I-GV automated guided vehicles

The I-GV family includes three models, available in different versions meeting different needs and handling multiple types of WLU (Workload Units), such as pallets or boxes. The available models are the following:

I-GV Outrigger – Medium: lifting up to 2500 kg;

I-GV Outrigger – Big Size: lifting up to 5000 kg;

I-GV CW – Medium: lifting up to 1800 kg;

I-GV CW – Big Size: lifting up to 4000 kg;

I-GV Box: lifting up to 15 tons.

To discover all the technical features of the various models of those automated guided machines, download the brochure.

Safe and efficient handling

The I-GV system employs advanced traffic management, powered by the Next Generation System Manager, a cutting-edge technology that leverages AI-developed algorithms. This innovation allows for unparalleled system flexibility and customization, significantly improving order flows, reducing stalling, and boosting overall vehicle efficiency.

Data from I-GV's certified sensors and 3D environment cameras meticulously regulate the vehicle’s perimeter safety zones, ensuring obstacle detection and avoidance in compliance with current ISO standards. This meticulous attention to safety guarantees that I-GV movements are always completely safe and efficient, without compromising functionality. Additionally, the user-friendly HMI and calibration wizard make the system extremely accessible and easy to operate.

Lithium battery, longer lasting and environmentally friendly

System Ceramics’ I-GV models of automated guided vehicles are equipped with lithium batteries, which offer several key advantages over lead-acid batteries. The first and main advantage is reduced recharge time: a lithium battery fully charges in one hour and provides up to eight hours of use, while a lead-acid battery typically requires an eight-hour charge for the same amount of operating time. In addition, lithium batteries have a higher energy density, which means they can deliver the same power while being significantly smaller and lighter than their lead-acid counterparts.

Lithium batteries are also more efficient in terms of medium- to long-term use, as they assure a much higher number of charge and discharge cycles. Furthermore, they do not require regular maintenance or recharging, unlike lead-acid batteries.

Finally, lithium batteries are safer and more environmentally friendly, as they do not emit gases during charging, eliminating the need for ventilation systems in charging areas.

Choosing System Ceramics automated guided vehicles also means always having a team of experts ready to intervene 24 hours a day to resolve any problems or technical emergencies that may arise.