BRINGING PRINTHEADS BACK TO NEW: System Ceramics’ advanced maintenance solution

Imagine turning back the clock on your printheads - restoring them to peak condition, extending their lifespan, and achieving all of this while slashing costs and reducing your environmental impact. With System Ceramics’ printhead regeneration service, this isn’t a vision for the future—it’s a solution for today.

When the first signs of wear and tear begin to occur, many manufacturers feel that replacement is the only option. But System Ceramics offers a smarter alternative: a high-quality regeneration process that ensures your printheads work like new, without the expense and waste of buying new components.

A Process Engineered for Excellence

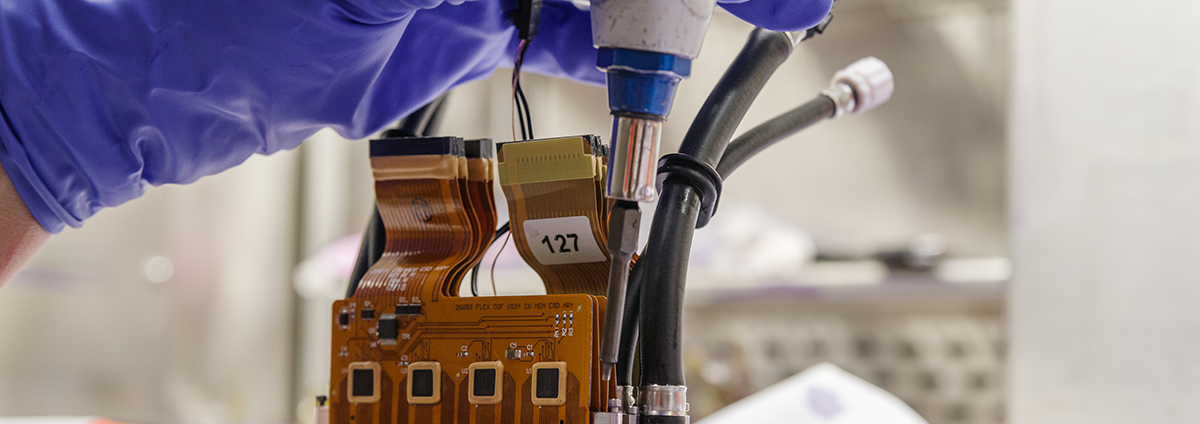

At the heart of System Ceramics’ regeneration service lies a meticulous process, built on decades of expertise and fine-tuned to meet the unique demands of the ceramics industry. Each printhead undergoes a comprehensive analysis to assess its condition and determine the best course of action.

Depending on requirements, reconditioning, complete remanufacturing, or even modification to change polarity and achieve total compatibility with water-based or solvent-based inks can be opted for. Each step in the process is designed to restore these components and ensure flawless performance.

Reconditioning is not just about replacing worn-out parts; it’s about restoring every critical element. Cleaning and flushing cycles ensure no residue remains, while components subject to wear are replaced with precision. Full regeneration goes a step further, involving more comprehensive replacements, including the collar, which gives the printhead a fresh start—complete with a new serial number.

For manufacturers needing versatility, polarity modification allows a printhead to transition seamlessly between different ink types, opening new production possibilities without requiring additional equipment.

Results You Can Trust

System Ceramics’ regeneration service is proven, with over 10,000 printheads processed through this rigorous system and an impressive 92% success rate. Each one is subjected to stringent testing, including thorough cleaning of all nozzles and a full reset verified by print tests.

With 48-hour delivery times available for many models, manufacturers experience minimal downtime, allowing operations to continue without major interruptions. And with 10 local repair centers worldwide, support is always within reach.

Sustainable Solutions for a Greener Future

Regenerating printheads isn’t just economically advantageous - it’s a commitment to sustainability. By extending the life of existing components, System Ceramics helps manufacturers reduce waste and lower their environmental footprint. This aligns with the industry’s growing focus on responsible production practices and positions regeneration as a forward-thinking choice for companies striving to balance profitability and environmental stewardship.

A Smarter Way Forward: Why System Ceramics Stands Out

Choosing regeneration is a smarter way to operate. By investing in System Ceramics’ service, manufacturers gain more than restored printheads; they gain peace of mind, knowing they’re working with a team of highly qualified professionals dedicated to their success.

If the ceramics industry thrives on precision, durability, and innovation, then System Ceramics’ printhead regeneration service embodies all three. It’s time to rethink maintenance, embrace sustainability, and unlock new levels of efficiency.