Precision Robotics for Optimized Handling

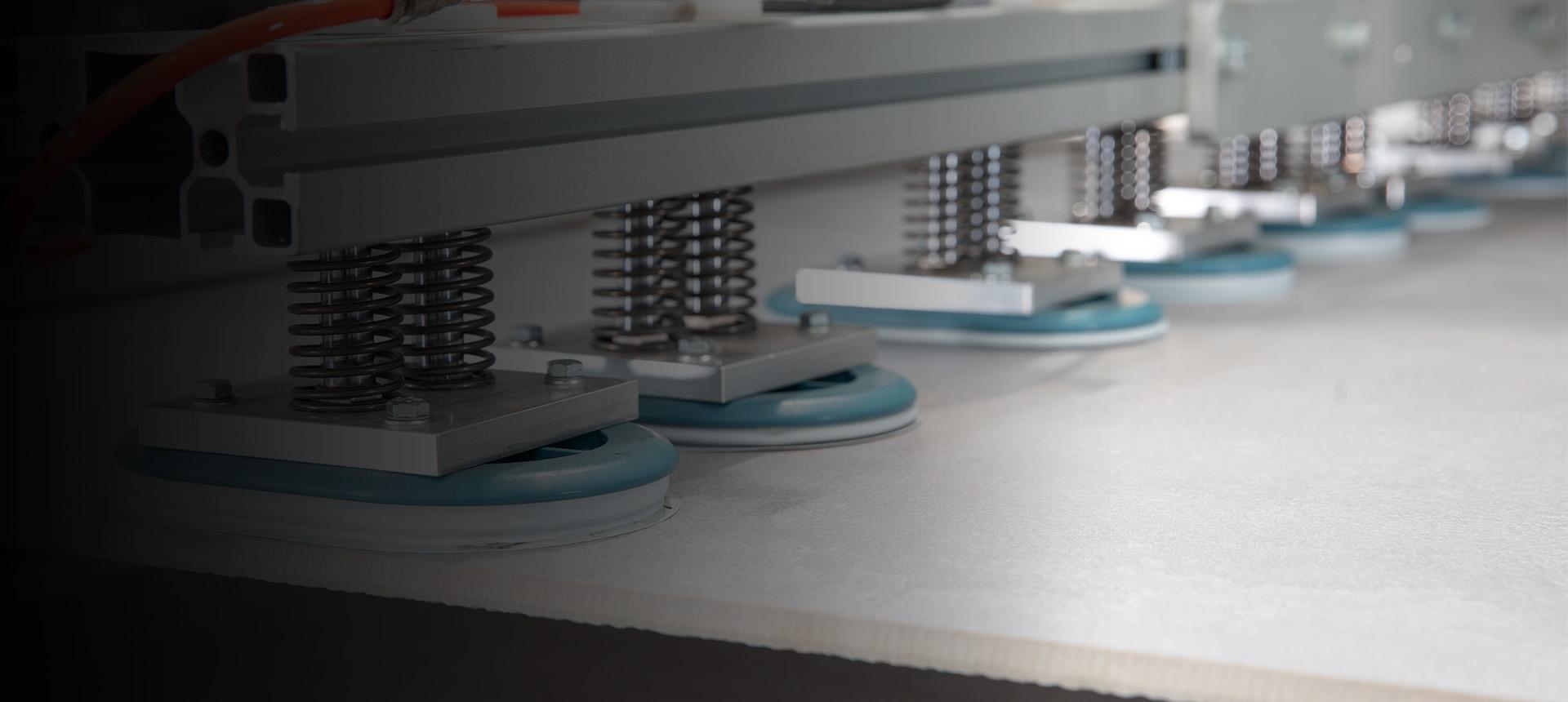

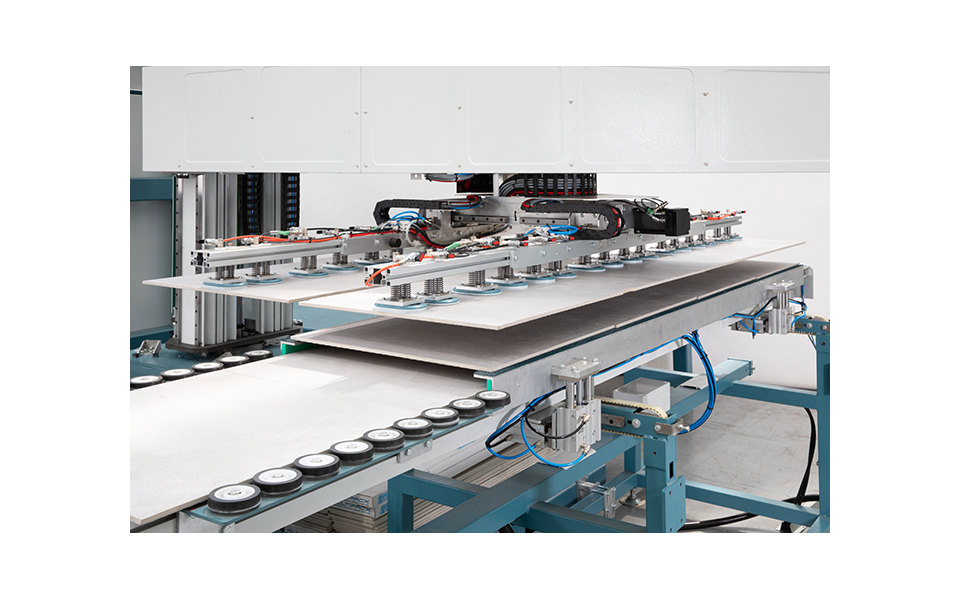

At the core of Rotostore is its advanced 4+1 axis robotic system, designed specifically to handle fired ceramic materials with precision and speed. This system’s engineering excellence is centered on optimizing end-of-line handling, where precision is essential to maintaining high production standards. The robotic arm, equipped with a patented double-row suction cup mechanism, provides the flexibility to lift either two rows of tiles simultaneously or a single heavier row, depending on production needs.

This dual capability makes Rotostore highly adaptable to varying weights and tile configurations, allowing it to handle diverse production requirements with ease. The system’s precise robotic movements are meticulously calibrated, ensuring tiles are consistently and accurately placed on loading beds. By minimizing errors and optimizing workflow, Rotostore guarantees the reliability needed for large-scale production environments.