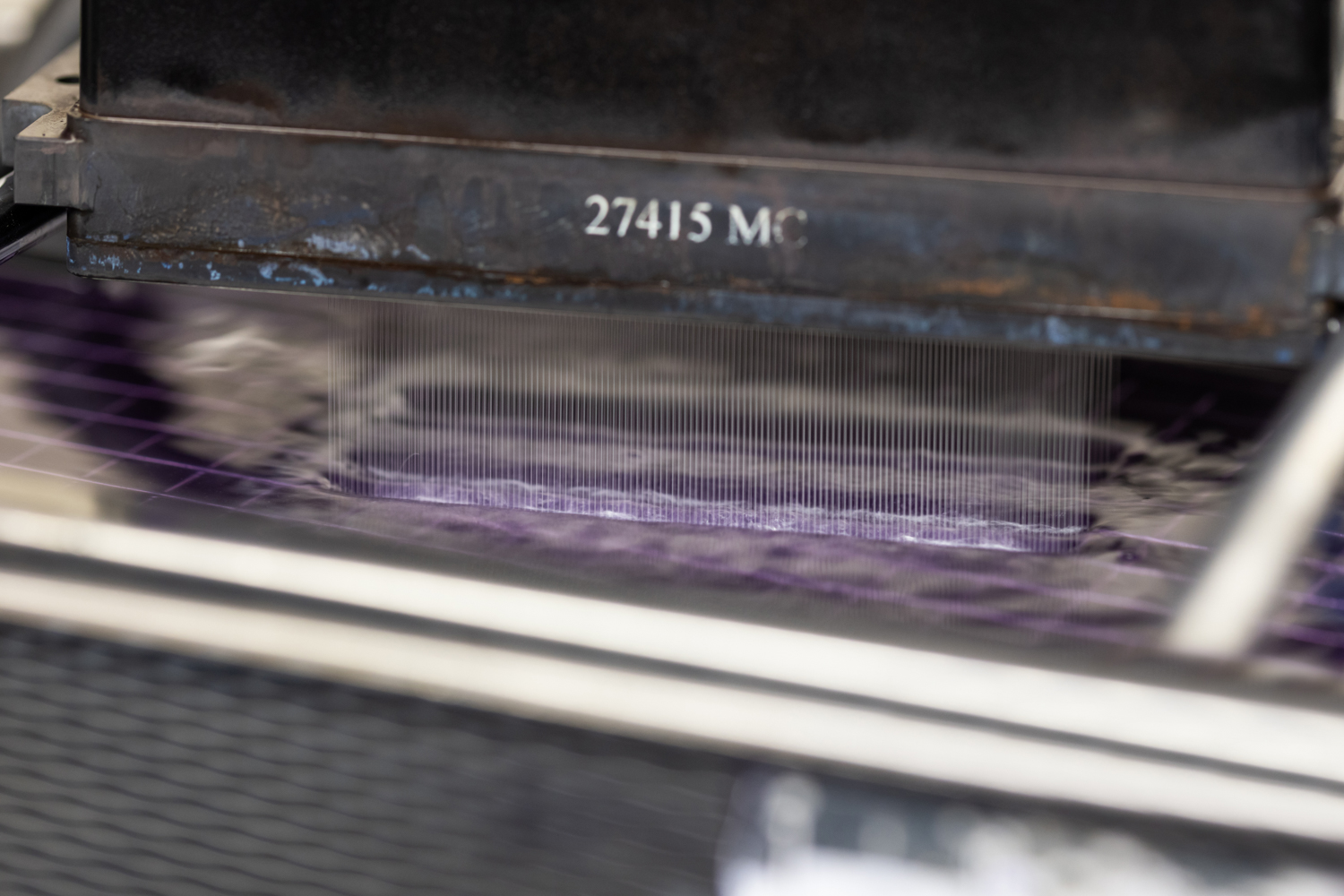

Printhead regeneration

The printhead restoration/repair activity is carried out through multiple processing cycles, leading to the following final results:

RESTORED printhead: printhead subjected to flushing cycles to achieve optimal print quality, without replacing mechanical and/or electrical parts (not applicable to water-based printheads).

RECONDITIONED printhead: printhead restored to full working condition following the replacement of several worn components and multiple cleaning/flushing cycles, with final testing and print tests.

REMANUFACTURED printhead: printhead brought back to the condition of a new one, including most of the reconditioning processes plus the replacement of the collar, resulting in a new serial number.

POLARITY CHANGE: printhead subjected to polarity inversion to support water-based inks or solvent-based inks.

NON-REPAIRED printhead: printhead that has undergone analysis via test printing and an initial cleaning, from which the impossibility of restoration is evident.