Why advanced vision inspection systems are changing the way ceramics are made

The answer lies in a fundamental shift: what was once verified by the human eye must now be measured, classified and archived by systems capable of detecting variations invisible to manual inspection. In ceramic production, every surface is a field of variables (colour, glaze, texture, reflection) that determine the coherence of an entire batch.

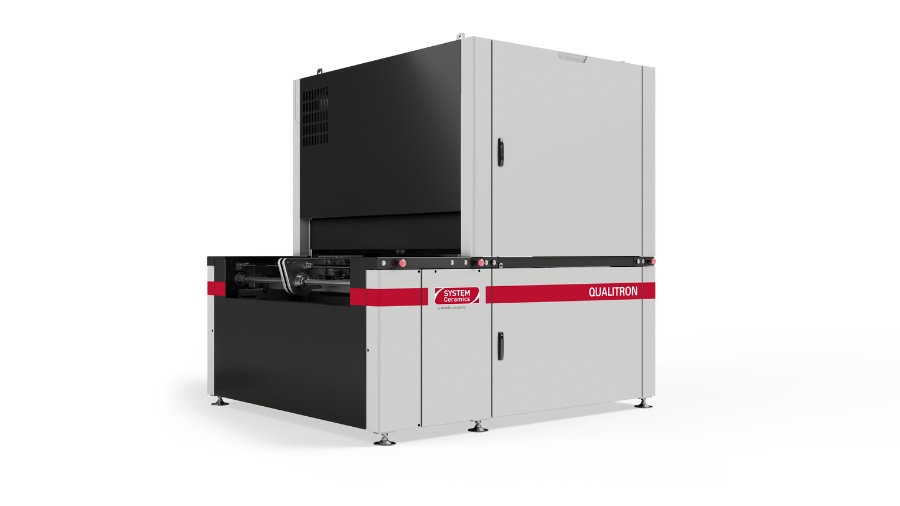

As digital printing technologies expand decorative possibilities and surface finishes grow more complex, the limitations of visual inspection have become evident. System Ceramics has developed Qualitron, an advanced vision inspection system that integrates optical analysis, mechanical precision and digital control to deliver reliable and repeatable quality on every ceramic production line.

The changing role of quality control

Ceramic manufacturers operate in environments where precision and speed must coexist. Manual inspection requires time and sustained attention and results can vary from one operator to another. Automated vision inspection systems respond to this challenge by analysing, classifying and recording every detail with constant accuracy. Modern vision and control systems work without interruption, providing objective data for quality assurance and process optimisation. Within this field, Qualitron represents one of the most advanced technologies for maintaining full control of product quality at industrial scale.

Qualitron: the vision inspection system for ceramic surfaces

Qualitron performs a complete inspection of tiles and slabs, analysing both surface decoration and structural composition. The system identifies tone differences, printing bands, stains, glaze irregularities, and verifies the correct synchronisation between structure and decoration.

It is equipped with a network of three latest-generation cameras, two grayscale and one colour, and a System Electronics LED lighting system. The lighting includes three to four sources, optimised for ceramic materials, and features a self-setting function that automatically adjusts to changes in tile thickness. This ensures precise alignment and stable illumination even on reflective or polished finishes.

Through this combination, Qualitron guarantees accurate and consistent inspection across every product format.

Detecting defects with consistency

Qualitron detects and classifies a wide range of defects:

- Tone variations after firing

- Decoration defects such as drops, bands or spots

- Glaze imperfections like pitting, lumps or irregular distribution

- Synchronisation mismatches between graphics and structure

It operates at up to 200 pieces per minute, allowing fast production lines to maintain their full speed without compromising quality. Each tile is inspected individually, ensuring complete traceability and reducing the number of non-conforming first-choice products.

Three models for different production scales

The versatility of Qualitron allows its integration into any ceramic production line. It is available in three models, designed for various surface dimensions and production needs:

Model | Surface reading dimensions | Best for |

Qualitron | 600 × 900 mm (up to 1200 mm) | Standard tiles and medium formats |

Qualitron BS | 1200 × 1800 mm (up to 2400 mm) | Large tiles and slabs |

Qualitron XXL | 1800 × 3600 mm | Very large slabs and panels |

All versions share the same inspection technology and reliability. The motorised transport enables quick format changes and guarantees stability during scanning, making Qualitron one of the most adaptable vision and quality control systems available today.

Software intelligence and data traceability

At the heart of the system lies Software 4.2, designed to combine operational simplicity with analytical precision. Its self-learning algorithms refine the detection process during operation, continuously improving accuracy.

Through integration with Hypermate, Qualitron can archive, extract and consult data in real time. Each tile generates a complete data record, including process images and defect information, enabling advanced analysis and preventive adjustments.

This continuous data flow transforms inspection from a static check into a dynamic process of improvement and optimisation.

Creasync, the digital standard for quality

Among Qualitron’s most distinctive features is Creasync, a patented technology developed exclusively by System Ceramics. Creasync compares each inspected tile with the original digital graphic file used in the printing phase.

This innovation removes the need for physical samples, shortens setup times and increases inspection accuracy. The system recognises graphics even on rotated (180°) or sub-format tiles, ensuring correct positioning for products with random faces.

Main advantages:

- Objective, data-based classification

- Reduced machine setup time

- Reliable correlation between digital design and physical output

- High precision on large-slab and sub-format production

Evolving through Artificial Intelligence

System Ceramics is currently investigating the integration of artificial intelligence to further enhance Qualitron’s analytical capabilities and detection accuracy. This development aims to increase the system’s efficiency and responsiveness, confirming the company’s commitment to innovation in AI-driven vision and control systems.

Precision as a production standard

In a field where reliability defines reputation, Qualitron offers manufacturers full control over quality. Its combination of advanced optics, intelligent software and patented comparison technology ensures precise, repeatable inspection across every production scale.

For ceramic producers seeking measurable quality and data-driven control, Qualitron stands as a comprehensive solution for continuous improvement and manufacturing excellence.

Discover more about System Ceramics’ vision inspection systems, download the official brochure and contact us for a detailed consultation on how Qualitron can be integrated into your production line.