14 March 2024

An even more sustainable ceramic decoration with System Ceramics

In the international ceramic scenario, increasingly sustainable innovation is dominating the evolution of major markets. From products to processes, respect for man and the environment goes hand-in-hand with attention towards raw materials, recycling and energy saving. Technology plays an essential role in determining the path towards an informed transformation and in guiding enterprises towards a constant upgrading of their competitiveness. System Ceramics bases its actions on these responsibilities and has always been at the forefront with disruptive technologies, often making breakthroughs in ceramic production.

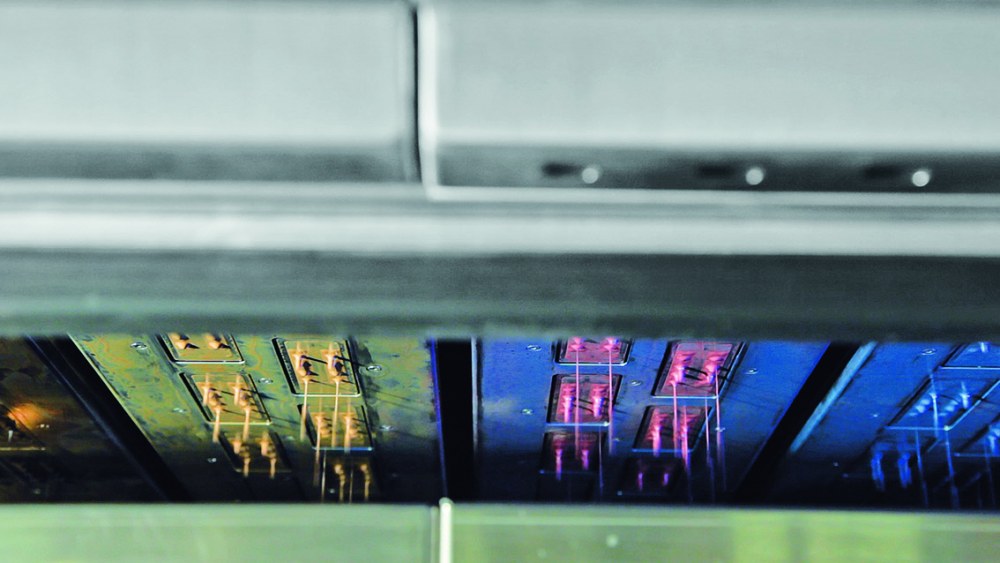

This is what has happened in the context of ceramic decoration, in the shift from analogic to digital: with Rotocolor already in 1994, Creadigit in 2011, then Creadigit Infinity, thanks also to the close collaboration with FUJIFILM Dimatix®. System Ceramics has launched a veritable co-design that has led to the first entry of Dimatix into the specific world of digital printing for ceramics and the establishment of ultra-high-resolution drop-on-demand piezoelectric inkjet printheads.

Today the company is the pioneer of a new evolution: the conversion of digital printers from solvent-based to Water-Based. This is the result of over 4 years’ work, carried out with accurate tests on over 1000 heads and more than 1000 tons of ink and glue. This research and the constant search for improvement has led to the definition of high-performance drop-on-demand printheads with water-based ecological inks, easy to integrate, with single color operation and 400 drops per inch resolution.

The acquisition of such progress opens up interesting opportunities for the ceramic sector, today projected towards a qualitative upgrade that sees at the forefront the continued affirmation of large slabs, also for furnishing and interior design uses, with the consequent need to seek a technical and aesthetic result of the highest prestige.

The test results obtained with the new water-based inks have confirmed clear advantages: first of all, an improved print definition determined by a more rapid absorption capacity by the substrate, and by the absence of water repellency on the glaze which, in turn, benefits from a more advanced application process.

The use of water-based glues also produces excellent results: more adhesive power, a longer drying time and, as a result, greater flexibility.

This passage forms part of System Ceramics’ green philosophy, aimed at consolidating important benefits: a net improvement in the quality of the working environment, with the elimination of irritating and harmful smells inside the company; the reduction of polluting elements into the atmosphere by around 40-50%; the elimination of afterburners, with consequent reduction in CO2 emissions and energy savings. It is an important step forward, therefore, increasingly aligning the evolution of the ceramics industry with respect for the environment and confirming System Ceramics’ standing as leader for made in Italy sustainable technologies.