Armazenamento cerâmico, a chave do sucesso

Muitas vezes, a fase de armazenamento é vista como menos importante ou pouco interessante dentro de todo o processo produtivo cerâmico; no entanto, as máquinas de armazenamento são cruciais para o correto funcionamento de uma instalação de produção.

A System Ceramics sabe-o bem, sendo reconhecida como líder na movimentação e no armazenamento no setor cerâmico, respondendo às exigências do mercado com uma ampla gama de sistemas de armazenagem. Cada máquina é concebida para resolver um desafio específico e adaptar-se ao contexto produtivo do cliente.

Armazenamento cerâmico: as soluções consolidadas da System Ceramics

A System Ceramics trabalha há décadas com sistemas de armazenagem, desenvolvendo máquinas já bem conhecidas e consolidadas no setor graças à sua fiabilidade e durabilidade ao longo do tempo. Um exemplo é o Robofloor, uma das máquinas mais difundidas no mercado, utilizada para as necessidades de carga e descarga de caixas e linhas com ladrilhos e placas cozidas. O Robofloor está equipado com uma mesa de sucção utilizada também em muitas outras soluções logísticas; isso o torna ideal para atender às exigências de grandes produções em termos de metros quadrados e formatos.

Outro exemplo é o Fastroll, uma máquina tradicional e muito popular, apreciada pelas dimensões compactas combinadas com a capacidade de armazenar grandes quantidades de material e pela simplicidade da estrutura e manutenção. É um sistema de armazenamento por rolos com boxes cujo movimento dos planos se faz por colunas, permitindo carga e descarga com buffer de produto cru ou cozido.

Além disso, está equipado com software proprietário da System Ceramics, que possibilita maior flexibilidade no desenvolvimento de atualizações e soluções personalizadas.

As tecnologias do futuro

Como os sistemas de armazenamento são essenciais para garantir eficiência, flexibilidade e continuidade ao longo das linhas de produção, a oferta da System Ceramics está em constante expansão, com soluções cada vez mais específicas para cada necessidade e para cada situação produtiva. Falando de máquinas atualizadas e de nova geração, o Multistore é certamente uma das adições mais interessantes ao portfólio: um dispositivo automático para a movimentação e o armazenamento de material cozido, considerado a evolução do Robofloor. A sua inovação consiste nas dimensões reduzidas que, além da vantagem de ocupar menos espaço, se traduzem em movimentos ágeis e eficientes, com um consequente menor consumo de ar e energia.

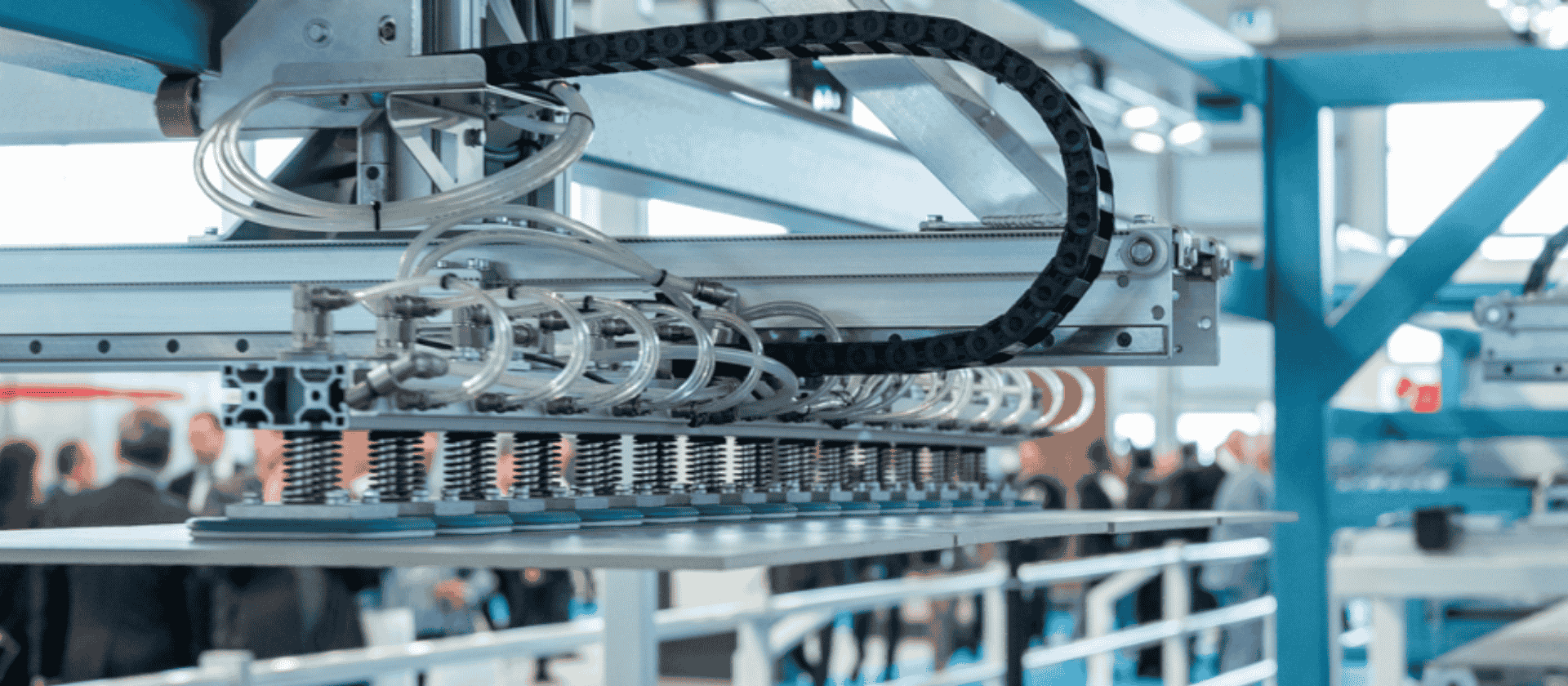

Um trio altamente inovador é composto por Multicompenser, Multibuffer e Multistorage, nascidos de uma base tecnológica comum e posteriormente desenvolvidos para satisfazer necessidades operativas diferentes, oferecendo características, estruturas e níveis de complexidade distintos.

- Multicompenser foi concebido principalmente para atuar como buffer entre as máquinas a montante e a jusante, sendo a solução mais eficiente do mercado em termos de capacidade de armazenamento por metro quadrado de área ocupada.

- Multibuffer é uma solução compacta, flexível e mais completa do ponto de vista mecânico. O seu funcionamento “peça a peça” permite uma melhor gestão das necessidades individuais de armazenamento e das pequenas/médias emergências, tornando-o perfeito para linhas produtivas mais exigentes.

- Multistorage, graças ao elevado grau de modularidade, é projetado para necessidades intensivas de armazenamento cerâmico e para movimentações de longo prazo, oferecendo um armazenamento estratégico que preenche lacunas operativas e sincroniza eficazmente os fluxos de produção.

Cada sistema de armazenamento cerâmico possui características e vantagens específicas: descubra mais no nosso site dedicado.

Por que é fundamental investir num bom sistema de armazenamento cerâmico

Um processo de armazenamento bem organizado traz inúmeras vantagens ao polo produtivo.

- Antes de mais, e mais importante, garante a otimização do espaço, frequentemente já saturado, dentro da instalação.

- Outro benefício é a continuidade produtiva, mesmo em caso de abrandamentos ou paragens temporárias a montante ou a jusante da linha, sem comprometer a flexibilidade ou a velocidade de produção.

- Além disso, escolher o sistema de armazenamento adequado reduz o consumo energético, um aspeto essencial num contexto cada vez mais orientado para a sustentabilidade e para o respeito pelo ambiente.

- Por fim, a seleção da tecnologia certa de armazenamento permite a movimentação de materiais cada vez mais delicados, como as placas ultrafinas.

Escolha o parceiro tecnológico certo e olhe para o futuro

Como já mencionado, as soluções de armazenamento desempenham um papel crucial no processo de produção cerâmica, pois são essenciais para otimizar o fluxo de trabalho e a eficiência produtiva, garantindo ao mesmo tempo uma manipulação precisa de materiais delicados e operações fluidas em todas as fases, tanto antes como depois da cozedura. Por isso, a System Ceramics não se foca apenas no armazenamento, mas aborda a intralogística com uma visão mais ampla, apostando nos I-GV, veículos automáticos de última geração que permitem otimizar todo o ciclo produtivo.

Trabalhamos continuamente para apoiar as instalações produtivas de hoje e de amanhã, com uma gama versátil de tecnologias de armazenamento que vai desde máquinas consolidadas e fiáveis até aos sistemas mais inovadores. A nossa palavra-chave é otimização.