Digital Industrial Design

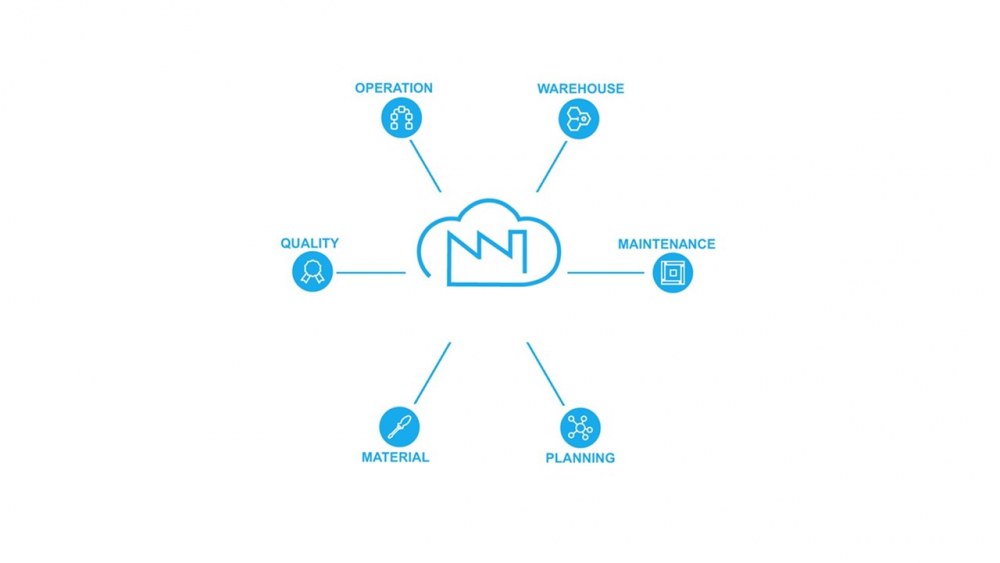

Hypermate powered by Prime is a platform of software services conceived and developed by System Ceramics. The highly integrated and connected system permits the organization of information flows of entire ceramic production factories. As a form of Manufacturing Operations Management (MOM), it’s a solution able to offer complete visibility of a factory’s production processes in their entirety, with the aim of constantly improving production performances.

The demand for product customization, the reduction of lots, as far as the possibility of processing special pieces, are the new challenges that contemporary ceramic producers have to face. A complete digitalization of processes, the use of shared resources and the efficient management of data are fundamental elements for the sustainable development of the new manufacturing paradigm .

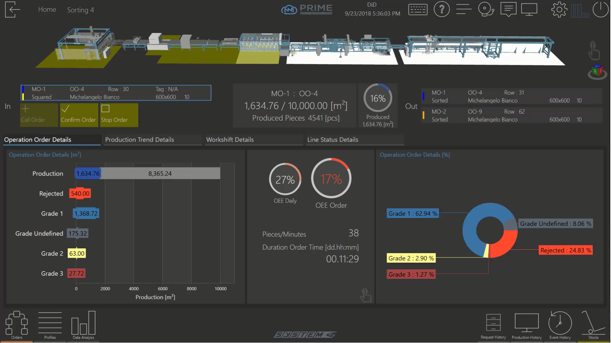

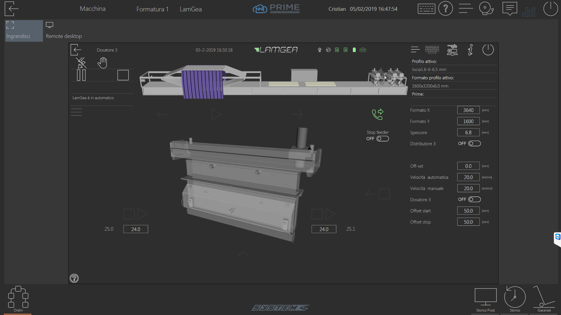

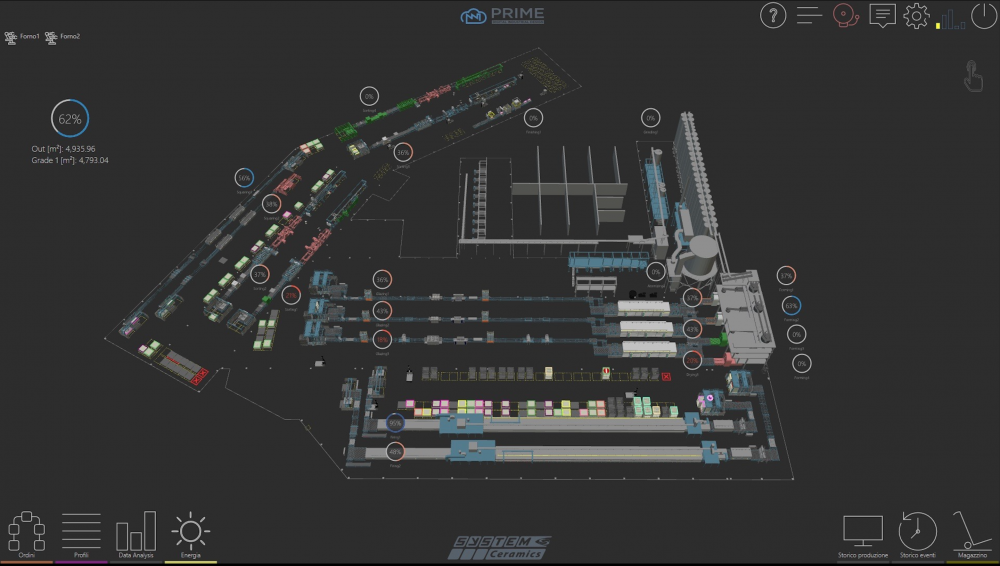

The Hypermate powered by Prime Digital Twin controls the entire ceramic production cycle: from the entry of the raw materials to the compilation of a picking list of the finished product. Thanks to a unique latest-generation graphic interface and the use of 3D technologies, ceramic production systems can be represented in all their completeness and dynamism, permitting a virtual reconstruction of the entire production cycle.

Prime consolidates all the ceramic production processes and improves the management of product quality, planning and advanced timing, facilitating flexibility and speeding up time-to-market.

Hypermate powered by Prime’s advantages:

- Real time 3D and natural interface

- Control of entire ceramic production systems in a number of factories

- Management of standardized data to simplify ceramic production processes

- Gathering of simple information for guiding decisions

- Improvement of communication between the company and the machines supplier

- Reduction of product change times: the parameters and the ceramic product “recipes” are transmitted with a click

- Optimization of lots production, also in very small quantities

- Monitoring and management of production costs for accurate data

- Towards the "zero defect" target: increasing in the quality of the product, the company’s state of health improves.