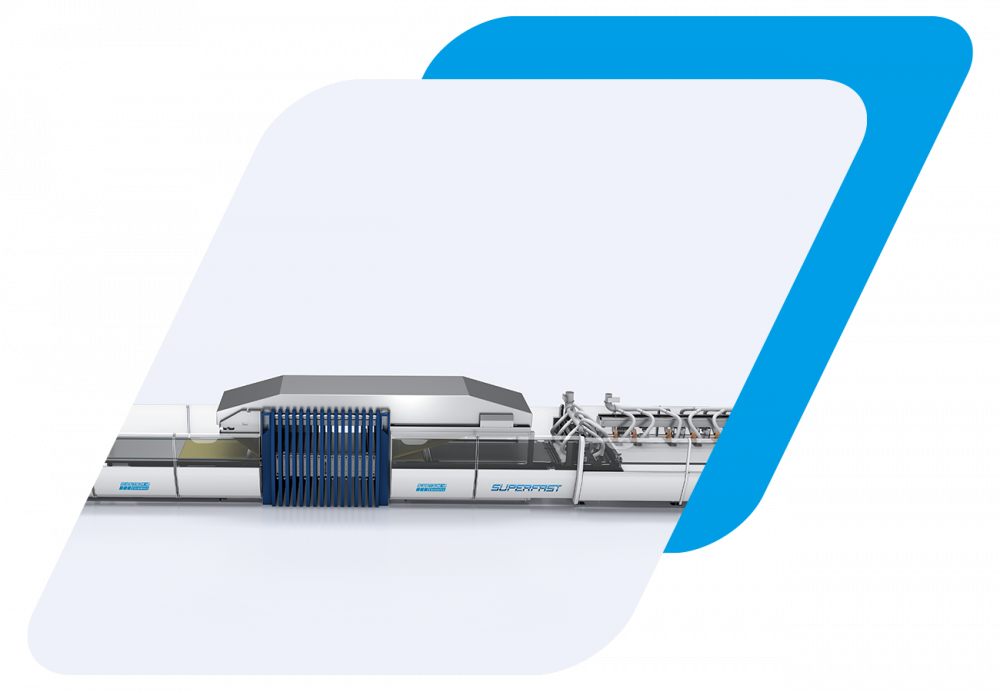

The one-of-a-kind press without mold for the tile industry.

High speed, flexibility and sustainability are the key features of the innovative ceramic press without mold for tile industry. Superfast can produce all formats starting from the 60, 80 and 90 cm module with thickness from 3 to 30 mm. This operation occurs digitally via software. The technology guarantees energy saving up to 70% and the full recovery of material coming from the pressing and cutting phase for a state-of-the-art sustainable industry.

Five models for a unique flexibility:

- Superfast 17.000 maximum format > 1200x2400 mm

- Superfast 19.000 maximum format > 1200x2700 mm

- Superfast 21.000 maximum format > 1200x3000 mm

- Superfast 22.000 maximum format > 1600x2400 mm

- Superfast 25.000 maximum format > 1200X3600 mm

Thanks to a system fitted with a single belt and which does not require a mold, Superfast makes it possible to produce with a flexibility never seen before for all traditional formats. Modules starting from 60, 80 and 90 cm and with thicknesses from 3 to 30 mm can be managed with a simple and rapid operation, setting-up the parameters via software.

Superfast guarantees considerable advantages in terms of time given that the replacement of the belt occurs in just 30 minutes and advantages interms of space given that it’s no longer necessary to store molds in the warehouse. All this leads to advantages in terms of costs.

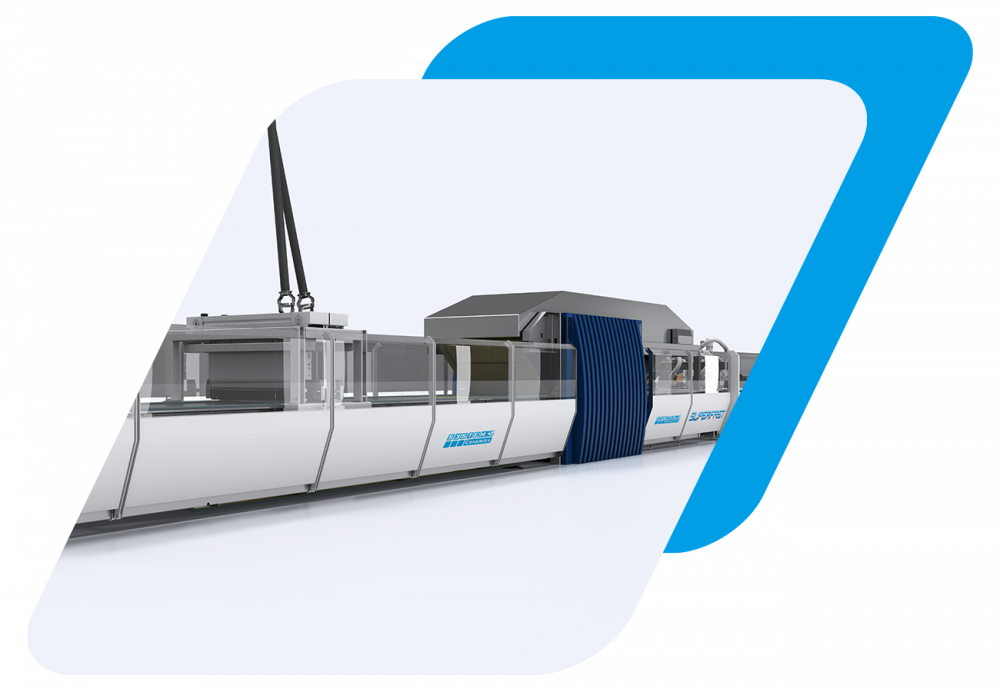

With Superfast, System Ceramics has exploited its innovative capacity to the full, promoting a technology that makes it possible to cut the ceramic surface after pressing and before introducing it into the kiln, with consequent recovery of the ceramic material in excess in the pressing and cutting phase.

Superfast operates with a “zero waste” process in which there are no scraps. The recovered waste is dry-ground directly at the side of the press and is then mixed and introduced directly into the atomised spreading dispenser.

The atomized powders are laid on the belt with mobile dispensers linked to a doctoring system.

The thickness of the material layer is constantly monitored also after pressing so that in the event of any variations occurring (change in humidity or granulometry) as a result of the doctor blade, the retroactive control system is able to correct it and adjust it automatically in the subsequent cycle.

Thanks to the slow and even laying and to a pressing which is similarly slow and progressive, with still atomized material, Superfast guarantees:

- improved uniformity on the entire surface and maximum planarity;

- improved geometry of the fired piece with a caliber per side less than or equal to 2 mm

Since the atomized material is free to expand in the moldless pressing phase, no residual stress is generated with Superfast. This makes it possible to produce thicknesses from 3 to 30 mm, with a lower weight per sq.m

These characteristics imply:

- lower consumption of raw materials and energy

- lower consumption of tools for rectification and lapping

- less waste during the rectification phase

- greater economic savings

Superfast is able to process all classes of standard atomized materials, without requiring materials of particular types and/or with particular characteristics, permitting, in this way, great flexibility in the choice of input raw material in terms of humidity, smoothness and granulometry.

Besides stoneware, it’s possible to use red paste, monoporous paste, re-granulated dry-ground etc., with a consequent lowering of industrial costs.

With Superfast it’s possible to cut the ceramic surface after pressing and before being put into the kiln. It’s an automatic cutting system integrated with the line, which is managed in a simple way through software. Stocks are considerably reduced with this process, it being possible to produce on demand on the basis of requirements.

The material recovered in the cutting phase is dry-ground directly at the side of the press and then mixed and input directly into the dispensers for the laying of the atomized material.

The Superfast process is able to manage pastes with a mix of virgin and recycled atomized material, the latter to the extent of 50% (industrially tested value) and above.

Uniform laying and gradual pressing with still atomized material ensures greater uniformity throughout the surface for detail-proof flatness. The result is also an improved geometry of the fired tile and a caliber on each side of less than, or equal to, 2 mm.

Superfast is able to make a ceramic product without residual tensions, a fundamental characteristic for the subsequent malleability of the finished product.

Three-dimensional design

From an aesthetic point of view, every three-dimensional effect is achievable thanks to the possibility of laser engraving the upper belt starting from the graphic file. With the aid of high resolution and a depth of engraving of up to 3 mm and maximum geometric regularity, it’s possible to press up to four different patterns while maintaining the quality of the ceramic design and increasing aesthetic variability.

Superfast makes no compromises in terms of productivity: with a single press, Superfast can produce up to 24.000 sq.m. a day, a quantity normally achieved with at least 2 traditional presses. Moreover, Superfast is able to process all classes of standard atomized materials, without requiring materials of particular types and/or with particular characteristics, permitting, in this way, great flexibility in the choice of input raw material in terms of humidity, smoothness and granulometry.

A solution that represents a a further step towards a production philosophy that is inevitably changing for the better, moving towards customisation and just-in-time; by reducing energy consumption and raw material waste Superfast is positioning itself as sustainable technology working towards the future of ceramic industry.

Software | Type | MCI & HMI System Ceramics Property | |

|---|---|---|---|

Special functions | Fast Mode Thickness reader | ||

Belt | Type | Single upper | |

Time needed for the replacement | 30 minutes | ||

Product features | Caliber tolerance | +/- 2 mm | |

Thickness tolerance | +/- 0,2 mm | ||

Thicknesses | From 3 to 30 mm | ||

Sizes | Multiformat | ||

Pre-cut sizes | Superfast 17.000 > 1200x2400 mm

| ||

Foundations | Absent | ||

Monitor | New Copilot 21 pollici HD Wide Screen | ||

Efficiency | |||

Average productivity | Up to 24.000 m2 per day | ||

Body | All types | ||

Average power consumption | 0,1 kWh/m2 | ||

Energy saving | Up to 70% | ||

Scrap recovery | 100% | ||

Structures for production cycle | Up to 4 | ||

Connectivity | Prime | Ready | |